Tap into a world of knowledge regarding brake fluids and their significance in vehicle safety and performance. This comprehensive exploration doesn’t just hit the brakes at the basic mechanics. Delve deep into the chemical composition of this crucial aspect of automotive engineering, particularly understanding its primary components; glycol-ether and silicon-based elements. Furthermore, grasp the importance of color variations, their causes, and implications, an insight that would even pique the interest of artists. Would you like to know how to check your brake fluid color accurately? Watch out for a simple and effective, tech-friendly guide that reveals best practices and safety precautions. Lastly, see how technology continues to influence and innovate brake fluid manufacturing, quality-checking, and general efficiency. Enjoy this vibrant journey into the world of brake fluids.

Composition of Brake Fluid

The High-Tech Chemistry of Brake Fluid

In the phenomenal world of tech and automation, there’s always something new, groundbreaking, and outright fascinating. Today’s topic might not come directly from Silicon Valley or be about the latest piece of disruptor kit, but it’s undoubtedly as tech-tinged as it gets. Let’s dive into the world of cars, or to be more specific – brake fluids. The analysis of what they’re composed of reveals an impressive blend of chemistry and technology that facilitates our everyday commute.

At its core, brake fluid is a form of hydraulic fluid. Its principal role is to transfer force into pressure, and amplify braking force within the brake lines of an automobile. The composition of brake fluid is often misunderstood, with many believing it to be a simple substance. However, in reality, it’s a blend of intricate chemical compounds that play unique roles in the performance and safety of a vehicle.

Majority of brake fluids we use daily are glycol-ether based. These types of fluids include DOT 3, DOT 4, and DOT 5.1 (Department of Transportation classifications). The heart of glycol-ether based brake fluids is largely composed of two polyol precursors: ethylene glycol and diethylene glycol – substances also popular in the manufacture of powerful antifreeze solutions.

These ingredients are known for their high boiling points and low freezing points – factors that contribute to their effectiveness in maintaining a consistent viscosity throughout drastic temperature changes. After all, those are the conditions brake fluids face when a car operates in diverse weather conditions or races down the highway.

Along with these fundamental components, DOT 3 and DOT 4 brake fluids generally include additives such as corrosion inhibitors and antioxidants. These perform the role of prolonging the life of brake parts and inhibiting the growth of detrimental chemical bonds within the fluid, maintaining its integrity.

By contrast, DOT 5.1 brake fluid, a more advanced type often used in high-performance vehicles, takes the tech-level a step further. It includes various performance-enhancing chemicals to withstand extreme braking conditions better.

We mustn’t forget DOT 5 fluid, which is silicone-based rather than glycol-ether-based. Primarily used in military vehicles and antique cars, DOT 5 has an entirely different chemical profile. The primary ingredient is Polydimethylsiloxane (PDMS), a type of silicone known for extreme temperature stability and resistance to water absorption.

That’s the evolution of brake fluid for you – from the foundational yet efficient glycol ether-based solutions used in everyday vehicles all the way to the performance-enhancing and temperature-resistant solutions designed for extreme vehicular conditions. It’s a fusion of chemistry and technology occurring right under our nose, or more accurately, foot.

Color Variation and Significance

Moving forward, let’s delve into the manner in which the color of brake fluid alters over time, and underline its significance in automotive maintenance.

Brake fluid, over its lifespan, tends to undergo a color transformation due to its hygroscopic nature; and the changing color is a telltale sign of its condition. Fresh brake fluid is typically clear or light yellow, but it progressively darkens with use. With time and exposure to heat and moisture, this gradual color change occurs. The action driving the change is boiling point depreciation – brake fluid eagerly absorbs ambient moisture which catalyzes a reduction in its boiling point. Reduced boiling point, in turn, hampers the brake fluid’s overall performance.

Key elements to be mindful of include contamination and oxidation. These factors play a significant role in the color degradation. When brake fluid comes into contact with metal components within the braking system, it tends to absorb trace amounts of copper or steel – which essentially taints the fluid, causing it to darken progressively. Compounding the situation, oxidation, resulting from the brake fluid reacting with oxygen, can cause a reddish-brown discoloration.

Moreover, internal corrosion in the braking system can also influence brake fluid color, largely depending on the type of metal corroding. For instance, corroded iron could tint the fluid a reddish-brown color, while corrosion from copper components might lead to a green-brown hue.

The color-preference semantics for brake fluids are not sovereign trends, but firmly established industry guidelines that give a timely indication of maintenance requirements. While a clear or light yellow color indicates good health, a dark brown or black color underscores the need for service or replacement. It’s not simply a case of aesthetics, but a pivotal safety issue. Ignoring a significant color change in the brake fluid can compromise the entire brake system, causing grave risks to vehicle safety.

Utilizing technology to assess brake fluid condition serves efficacy. Devices such as brake fluid testers are quite effective in detecting moisture levels. However, coupling this with keen visual inspection of the fluid color will ensure a well-rounded maintenance approach – optimized for safety, and ensuring smooth braking performance.

In short, understanding the specifics of brake fluid color change is integral to vehicle maintenance, enhancing the safety and longevity of the brake system. Technological advancements alongside traditional methods appear to be the winning combination in efficient brake fluid maintenance.

Clearly, the role of brake fluid extends beyond simply transferring hydraulic force; its condition and color indicate vital aspects about the health of our braking systems. For those of us who swear by technology, let this be another reminder of how science and tech intertwine in our everyday lives, exacting a massive impact – even in something as commonplace as brake fluid.

How to Check Brake Fluid Color

Monitoring Brake Fluid Color: The Tech-Savvy Perspective

The color of your brake fluid, an otherwise overlooked aspect, plays an essential role in vehicle maintenance. For the tech-savvy, efficient, and pragmatic individual, keeping track of your brake fluid’s hue becomes not merely a task but a quest to understand the very inner workings of your vehicle better.

Much like Sherlock deciphering complex crime clues, or like a programmer skillfully deciphering lines of buggy code, identifying the color of brake fluid begins with a simple, yet crucial step: visual inspection. A direct, no-nonsense look at your brake fluid reservoir can unveil a tale of vehicle condition and maintenance needs.

As a new brake fluid ages, it tends to darken progressively, a phenomenon primarily driven by heat, moisture, and the gradual depreciation of the boiling point. This hygroscopic nature of brake fluid is a crucial fact that impacts vehicle performance over time. Emphasizing the color shift from a clear, light amber for new fluid, to a murkier dark brown, or eventually to a pitch black, as a significant indicator of the fluid’s health.

Contamination and oxidation also contribute to the fluid’s color degradation. Debris, water and air infiltration can accelerate this process, eventually leading to the need for a fluid change. It’s a clear case of the problem and solution binary, akin to an efficient cleanup of your computer’s hard drive or updating your smartphone’s operating system. Each can lead to optimal performance if addressed promptly.

There are times when the color shift, especially to a milky or cloudy hue, can indicate internal corrosion, primarily if particular metals like copper or iron are corroding. This insight immediately prompts for a change.

Industry guidelines play a vital role in identifying the necessary steps once a color change is noticed. Much like software patch notes or tech protocol updates, acknowledging and following these guidelines ensure the vehicle operates at its maximum potential, minimizing maintenance mishaps and reducing the risk of brake system damage.

But how does a tech enthusiast up their game in brake fluid maintenance? By utilizing advanced tech gear, of course, like the brake fluid tester. This handheld device measures the brake fluid’s water content, providing an accurate representation of the fluid’s condition. It’s the highly effective combination of analog traditional methods with the precision of digital technology.

Understanding your brake fluid’s color change remains a critical component in enhancing not only the longevity of the brake system but also the overall safety. It’s the synthesis of technological advancements with traditional methods that make for efficient brake fluid maintenance, a testament to the broader implications of the acute understanding of science and technology in everyday life.

Harnessing technology’s power to identify, monitor, and understand brake fluid color changes is no different from adopting a new software or gadget, a welcome challenge for tech enthusiasts. Lessons from our tech-saturated daily lives can not only extend to vehicle maintenance but also serve as a testament to technology’s transformative impact on everyday tasks. As tech enthusiasts, it’s these eureka moments in a garage or behind a computer monitor that are the hallmarks of our fascination with the ever-progressing world of technology.

Influence of Technology on Brake Fluid

As crucial as the properties and composition of brake fluids are, understanding the technologically-driven manufacturing process and the strides being taken to further enhance their function is equally important. Falling in line with the expanding digital age, the production and application of brake fluid have experienced notable changes due to advancements in technology, promising more efficient and safer brakes for motoring enthusiasts.

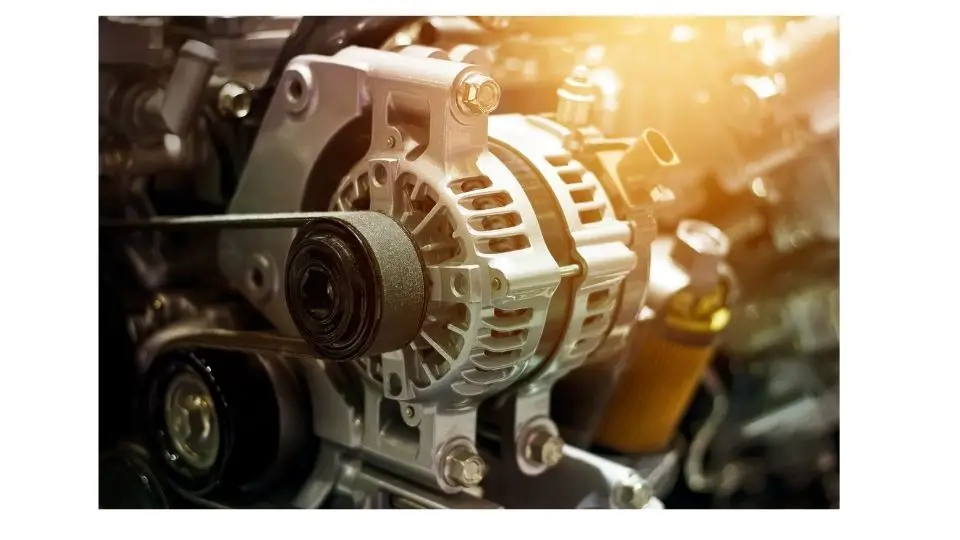

Robotics and automation have invaded nearly every industry, extending their reach to the manufacture of brake fluid as well. Computer-controlled machines now accurately mix the components of brake fluid at a scale and speed previously unimaginable, resulting in improved uniformity, reduced wastage, and increased production efficiency. The precision offered by these automated systems dramatically minimizes the margin of error in consistency and composition, ensuring each batch of brake fluid maintains the required standard.

Continuing on the production line, technology lends its hand in quality testing as well. Computer-assisted spectrophotometers inspect the chemical integrity of the brake fluid, assessing essential parameters such as boiling point, viscosity, and pH value. This precise tech-driven approach replaces earlier unreliable manual processes, providing more accurate test results and, thus, a higher-quality end product.

It doesn’t end at production; technology has significantly impacted the application and function of brake fluid in vehicles. Electronic Stability Control (ESC), an advanced technology that improves a vehicle’s stability, often relies heavily on brake fluid to achieve its functionality.

ESC systems use computer-controlled braking of individual wheels to help the driver maintain control in challenging driving conditions. For this sophisticated system to work seamlessly, a consistently performing brake fluid is absolutely critical. This underpins the drive towards high-performance brake fluids such as DOT 5.1, which possesses a higher boiling point to ensure maximum response in situations that engage the ESC.

In addition, technology has simplified the procedure of brake bleeding – an essential maintenance task involving the replacement of brake fluid. Bleeding kits equipped with One Man Bleed technology allow a single individual to perform the task efficiently. These devices work by creating a vacuum to draw out the old fluid, replacing it with fresh fluid, all without the need for a brake pedal depressor as with manual bleeding processes. This innovation has dramatically reduced the time and complexity involved in brake fluid maintenance.

Lastly, let’s not forget the indispensable contribution of technology in ensuring the quality of brake fluid is preserved in vehicles. Digital brake fluid testers effortlessly assess the moisture content, detecting small changes that might suggest a decrease in performance, allowing prompt action before any potential brake failure.

As we move towards an increasingly technologically-driven world, it becomes evident that automation, computerization, and digitization will further revolutionize brake fluid manufacture and usage. As such, understanding these aspects becomes an essential aspect of any technology enthusiasts’ knowledge base. For technology geeks and car buffs alike, observing how technology continually molds the world of brake fluids is nothing short of fascinating.

This exploration has undoubtedly expanded your knowledge horizon, as it has intricately dissected each critical facet of brake fluids. Armed with this invaluable information, you should now understand the physical and chemical properties of these essential automotive components, their complex composition, as well as the reasons behind their color variations. The tech guide should prove helpful in maintaining your vehicle’s optimal brake performance. More importantly, recognizing the heavy influence of technology and its role in enhancing this component of our vehicles should inspire confidence in riding and driving in today’s fast-paced era. Remember, your understanding and application of this knowledge could mean the difference between safe driving and an unfortunate incident. So, keep exploring, stay informed, and drive safe.

Tomas is a retired Chevy Auto Technician that brings decades of hands-on experience and expertise to the table. He’s also a father to two incredible daughters. He enjoys using his knowledge and experience to help you solve and find reliable information on Chevrolet vehicles. Whether it’s troubleshooting engine problems or providing tips for maintenance, Thomas is committed to helping Chevy owners keep their vehicles running smoothly and safely.