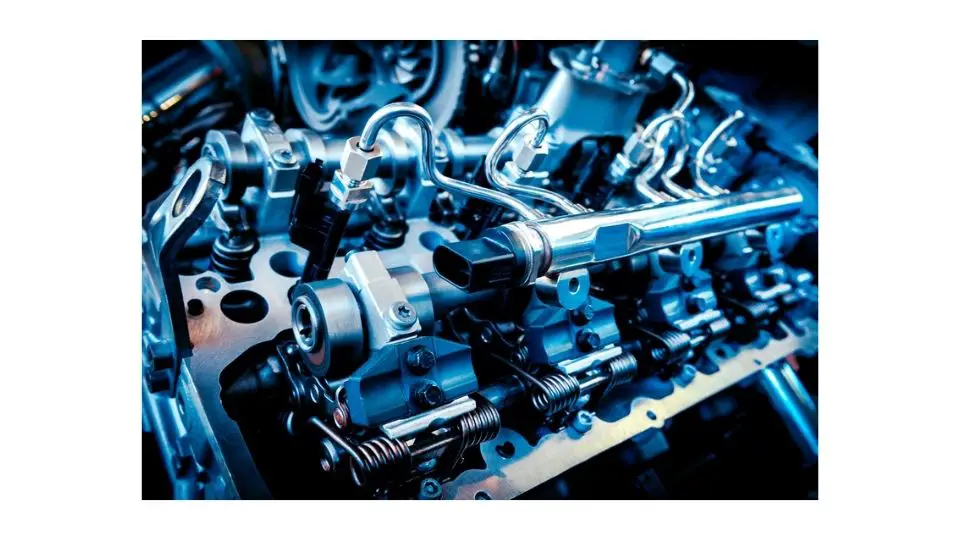

In this post, we are going to be looking at common LMM Duramax problems. The LMM Duramax is a 6.6L diesel engine that runs on several GM and Chevrolet trucks. This is one of their best engines that has outperformed Ford’s and Dodge’s engines of the same class.

The LMM Duramax runs mainly on GM Sierra trucks and Chevy Silverado HD trucks. Known for its great overall reliability as well as performance, there really are very few things that can be singled out when it comes to this engine. What are the problems that the LMM Duramax has?

In short, the most common problems with LMM Duramax are low fuel pressure, crankshaft and piston failure, Allison 100 transmission issues, leaking transmission lines as well as PDF system, and active regeneration.

When it comes to the engine itself, you will find that there are little to no issues that can be talked about. The problems arise from peripheral components to the engine. The other common reason that the LMM may have issues is due to modifications.

Brief Background of the lmm Duramax

The LMM Duramax was introduced in 2007 and was the successor to the LBZ which had been phased out. The introduction of the LMM was in response to new emissions regulations and the production run for this engine lasted until 2010.

If you have a Chevy or GMC diesel truck made between 2007 and 2010, you will most likely be running the LMM Duramax engine. Just like its predecessor, the LMM had a 6.6L powerplant.

The major difference between these two engines is that the LMM added active regeneration cycles to the DFP or diesel particulate filter system. This innovation managed to bring down emission levels significantly but it was at the cost of fuel economy. Just like other GM diesel engines of the time, it ran the Allison 1000 transmission.

How reliable is the LMM Duramax?

Just like its predecessor the LBZ, the LMM was a very reliable engine without any real problems of note. This engine is also tuner-friendly. The only real problems with this engine arise from modifications made to it.

If you are considering modifying yours in any way, consider consulting a reliable and experienced mechanic who has a good understanding of this engine. They will be well placed to give you the right advice as far as whet modifications work best with the LMM.

Not going that route could result in you not enjoying the reliability this engine is known for and possibly lead to thousands of dollars worth of repair work when something wrong happens with your engine.

The only thing that can be said against the LMM especially in comparison with its predecessor is that the fuel economy is worse. The good thing is that we get to protect the environment due to reduced emissions.

lmm duramax problems

DPF Failure on the LMM The DPF or Diesel Particulate filter with regeneration cycles is the main addition made to the LMM that was not available in the LBZ. This system works by capturing the diesel particulates in the soot. These particulates are then stored away.

Every 700 miles or when the particles reach 44 grams in weight, a regeneration process takes place where these particles are burned. If this did not happen, the system would get clogged up. The regeneration process requires 40 miles of highway driving to complete.

As opposed to city driving, highway driving allows enough heat to be generated to burn the particulate. When you only do city driving, the regeneration process may be interrupted. When this happens you will experience DPF failure.

Not allowing the regeneration to take place due to continued city driving will lead to DPF failure as well. To avoid problems with your DPF, make sure to drive on the highway often enough to allow the regeneration process to complete. The regeneration process will put backpressure on the engine which eventually leads to other issues.

Crankshaft and Piston Failure

This problem only applies in cases where you modify your LMM Duramax. The engine block on the LM is known to fail in high HP situations which are common in tuned engines.

In such scenarios, the pistons and crankshaft have been known to fail. If you intend to only run your LMM Duramax in stock mode only, you do not need to worry about this issue. Make sure to consult an experienced and reliable mechanic who has worked with Duramax engines before making any modifications to them.

Leaking Transmission Lines

When you experience hard shifting, transmission fluid (red) dripping under the engine or high transmission temperatures, the likely cause of this issue is leaking transmission lines. These lines are responsible for distributing transmission fluid in the Allison transmission.

Unfortunately, these lines have a design flaw that causes them to leak especially in cold weather or when the engine is cold. Consistent leaks result in low levels of transmission fluid which has the potential to damage internal components in the transmission. This common is so prevalent that some truck owners have to change them every 30,000 to 40,000 miles.

Low Fuel Rail Pressure

This problem is mostly associated with heavy towing in high-temperature situations like summer. More fuel is required meaning that the injectors and fuel pump overwork. This means that the rate of wear and tear is increased.

When either or both of these fail, the result is lower fuel pressure that results in reduced performance. This phenomenon is common in older trucks. It is usually accompanied by a P0087 code. To fix this will require replacing the fuel pump and/or injector.

Conclusion on lmm Duramax Engine issues

Like all other Duramax engines, the LMM is quite reliable and will give you a long lifespan especially when you maintain it well. There really isn’t much that you can expect to go wrong with it outside of the issues mentioned here. These issues are also very rare in occurrence and when they do occur, they are generally easy to fix.

Tomas is a retired Chevy Auto Technician that brings decades of hands-on experience and expertise to the table. He’s also a father to two incredible daughters. He enjoys using his knowledge and experience to help you solve and find reliable information on Chevrolet vehicles. Whether it’s troubleshooting engine problems or providing tips for maintenance, Thomas is committed to helping Chevy owners keep their vehicles running smoothly and safely.