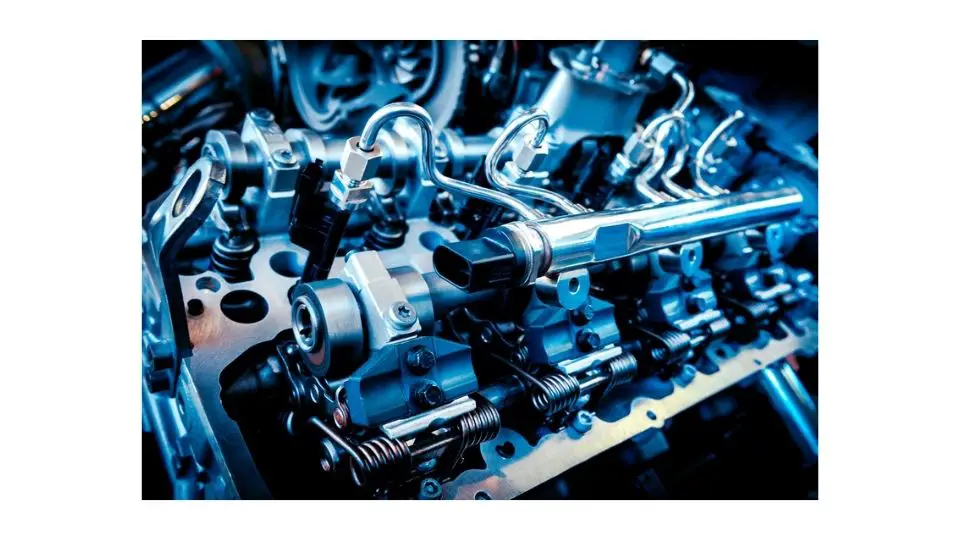

The LMM Duramax is a 6.6L diesel engine that runs on several GM and Chevrolet trucks. It’s one of their best engines that has outperformed Ford’s and Dodge’s engines of the same class. Still, it’s not perfect.

In this guide, we’ll look into the most common LLM Duramax problems, from leaking transmission cooling lines to fuel supply limitations under load. We’ll also show you how to spot and fix these issues without hassle.

But first, we need to answer an important question:

Is the LMM Duramax Reliable?

The LMM was a very reliable engine without any real problems of note. This engine is also tuner-friendly. The only real problems with this engine arise from modifications made to it.

If you are considering modifying yours in any way, consider consulting a reliable and experienced mechanic who has a good understanding of this engine. They will be well placed to give you the right advice as far as what modifications work best with the LMM.

Not going that route could result in you not enjoying the reliability this engine is known for and possibly lead to thousands of dollars’ worth of repair work when something goes wrong with your engine.

The only thing that can be said against the LMM, especially in comparison with its predecessor, is that the fuel economy is worse. The good thing is that we get to protect the environment due to reduced emissions.

LMM Duramax problems: 6 issues to watch out for

1. Leaking transmission cooling lines (poor crimp design)

Owners widely report leaking transmission lines on Allison-equipped trucks as mileage rises, often at the hose-to-hardline crimp. You’ll typically see red ATF misting the frame, crossmember, or exhaust.

GM issued multiple communications for line leaks and routing/abrasion concerns on HD trucks; while some bulletins target later years, the failure pattern (leak at the crimp joint or rubbed-through sections) is the same on previous models, including the LMM.

See the GM service bulletin describing weeping/leaks at the crimp joint near the auxiliary cooler and the fix to replace the inlet/outlet cooler pipes, plus later GM letters about cooler lines rubbing on the front frame bracket that can cause a leak.

Symptoms and quick checks

-

Fresh ATF on the lines or frame rails; drips at crimps = classic poor crimp design failure.

-

Slipping or flare shifts if fluid level drops too far. Owner complaints and NHTSA submissions specifically call out crimp separation and leaks that sprayed ATF on the exhaust.

Fix/prevention

-

Replace with updated OE lines or upgraded trans cooler lines (braided PTFE or aftermarket repair with flared unions). Tech threads discuss cutting before the crimp, flaring the steel, and using transmission-rated hose; several shops also sell complete trans cooler lines kits.

2. Diesel particulate filter (DPF) and sluggish acceleration

The LMM introduced a diesel particulate filter. When the DPF loads up (or when sensors/air-fuel issues prevent regeneration), the truck can drop into reduced power and feel like sluggish acceleration. GM’s TechLink outlines the logic: around a certain soot threshold, P2463 (DPF Soot Accumulation) sets and a service regeneration is required. Owners echo the behavior—“clean exhaust filter,” limp mode, and questions about forcing a regen with EFI Live or a dealer tool.

What to check before you blame the filter

-

Fuel system restriction (old fuel filter, air in lines), weak suction to CP3 under load (no factory lift pump), or MAF/air intake leaks can all prevent successful regens and mimic a plugged DPF. Owner diagnostics regularly find fuel filter restriction and MAF codes alongside “clean filter” messages, with many reporting improvement after adding a lift pump.

How to fix sluggish acceleration

-

Address air or restriction first (filter, filter head O-rings, lines), verify MAF readings and boost leaks, then perform a service regeneration if the DPF is genuinely loaded. GM’s guidance also advises against billing a service regen if a system malfunction exists—fix the malfunction, then regen.

3. Water pump seep and EGR cooler leaks (coolant loss without smoke)

Age and heat cycles can result in water pump seepage (weep hole) and EGR cooler leaks. Typical signs include intermittent low coolant and crusty residue around the pump, with no obvious external puddle. Numerous owner threads document drops from the water pump weep hole and mystery coolant loss later traced to the EGR cooler or hard-pipe gaskets.

Simple triage

-

Pressure-test the cooling system cold and hot; check the water pump weep hole, the hard-pipe O-ring at the pump, and EGR cooler joints. Threads from long-time members outline these leak points and “checklist” areas repeatedly.

Fix

-

Replace the pump if the weep hole drips; reseal hard pipes; pressure-test/replace the egr cooler if it’s seeping internally into the intake stream (often no visible smoke). Real-world reports note that towing in high ambient heat can accelerate failures on original pumps.

4. Fuel supply limitations under load (no factory lift pump)

The LMM uses a CP3 high-pressure pump that pulls fuel from the tank. Under heavy load or with mild tuning, marginal supply (small air leaks, clogged filters) can manifest as hesitation, sluggish acceleration, or low fuel-rail codes. Owners tackle this issue adding a lift pump to stabilize inlet pressure, smooth idle, and maintain commanded rail pressure when towing.

Symptoms and fixes checklist

-

New fuel filter

-

Inspect filter head seals

-

Clear lines

-

Verify MAF/air intake seal

You should also consider a lift pump to protect the CP3 and fuel system. Lift pumps are repeatedly credited for restoring power and preventing dropouts in stock trucks and mildly tuned rigs.

5. Oil in intake tract (PCV reroute debate)

Blow-by vapors entering the air intake can leave oil film in the turbo inlet and intercooler. Many owners debate PCV reroute versus catch-can solutions. They agree on several points, most notably:

- Reroutes keep oily mist out of the intake tract

- Catch cans add filtration but need service

- Poorly executed reroutes can cause visible blow-by discharge

Practical tip

If you’re stock and focused on long-term reliability, keep the system sealed and maintain the intake/filter often. If you install a reroute on a high-mileage truck, route discharge safely under the cab and away from hot exhaust components.

6. Cracked pistons (usually tuned or over-fueled)

You’ll find many complaints about cracked pistons, “EFI Live” timing, and wrist pin wear, often on trucks with heavy towing, high EGT, or aggressive tunes. The pattern across platforms is consistent: piston damage correlates with heat/pressure spikes (timing, fueling, load). While LML discussions dominate recent years, the failure mode is not exclusive to one generation—LBZ/LMM/LML can all be hurt with the wrong tune and abuse.

What to do

-

Keep EGTs in check, avoid excessive timing advance, and resist stacking tunes. Stock trucks driven within design limits rarely see this major issue.

Conclusion

Like all other Duramax engines, the LMM is quite reliable and will give you a long lifespan especially when you maintain it well. There really isn’t much that you can expect to go wrong with it outside of the issues mentioned here. These issues are also very rare in occurrence and when they do occur, they are generally easy to fix.

FAQs

Is the LMM Duramax a reliable engine?

Yes—kept stock, maintained, and not overheated, the LMM Duramax is a reliable diesel. The most common problems owners encounter are leaking transmission cooling lines, DPF/regen faults tied to air-fuel issues, and age-related cooling leaks. Addressing the trans lines with upgraded parts and keeping the fuel system/MAF in top shape prevents most headaches.

What year is the LMM Duramax best?

Mechanically, the previous models (LBZ) are often praised for fewer emissions components, but within LMM years (2007.5–2010) much comes down to mileage, maintenance, and condition of high-heat components (DPF, EGR cooler, pump, lines). A well-maintained late-build LMM that’s still stock can be an excellent vehicle for towing.

What is the lifespan of an LMM Duramax?

Many LMMs run 250k–400k+ miles with routine care. Lifespan depends on tuning, load, and cooling/DPF health. Keeping exhaust temps in check, servicing the filter/MAF, and replacing water pump and transmission lines proactively can materially increase longevity. (Owner longevity threads and service notes cited above.)

Which Duramax has crankshaft problems?

Crankshaft failures are discussed across generations, but most verified stock-truck reports cluster in LML threads. LBZ/LMM share the damper/flywheel pairing and can fail in abusive conditions, but it’s rarer on stock calibrations. See “broken crank” owner reports and hardware interchange notes.

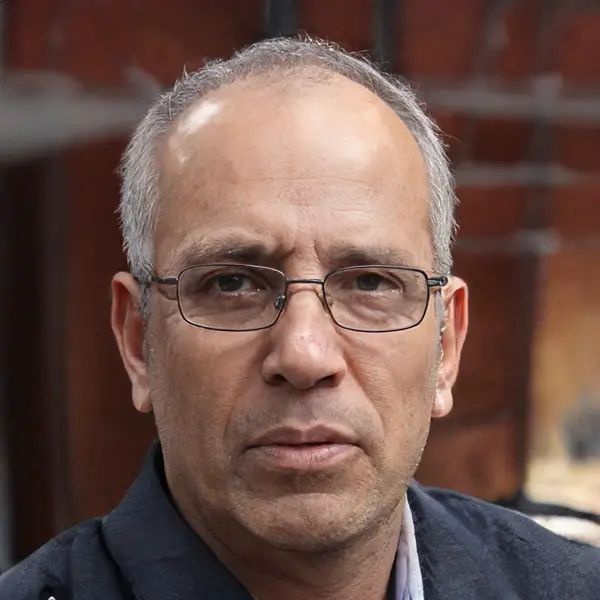

Tomas is a retired Chevy Auto Technician that brings decades of hands-on experience and expertise to the table. He’s also a father to two incredible daughters. He enjoys using his knowledge and experience to help you solve and find reliable information on Chevrolet vehicles. Whether it’s troubleshooting engine problems or providing tips for maintenance, Thomas is committed to helping Chevy owners keep their vehicles running smoothly and safely.